More Gunwales & Interior

December 2, 2019

December 2, 2019

Thanksgiving weekend with a host of family obligations and more cold weather makes for continued slow progress.

The transom patches are all set – I guess I'll be painting rather than varnishing this area.

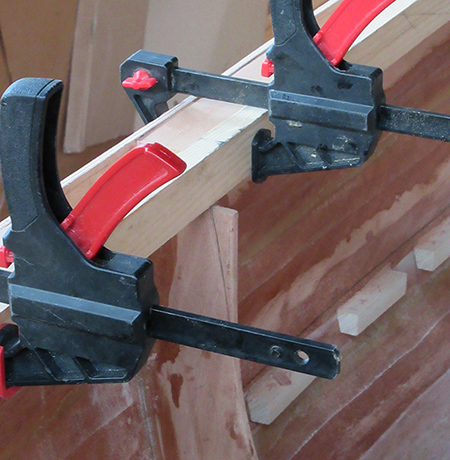

Back to work on the gunwales,.. the blocks are now evenly spaced and station forms have been cut back to accommodate.

I'm additionally reshaping them to align with the current inwale position (see pencilled cut line).

Here all the forms have been cut back to fit.

It's too cold to glue so I moved on to cutting the starboard frames to fit the inwale treatment.

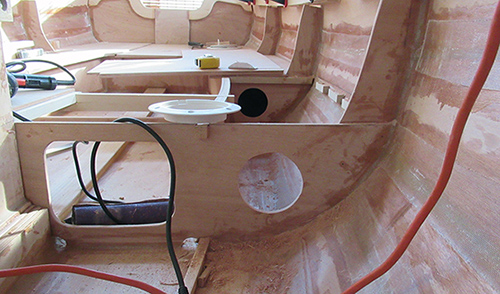

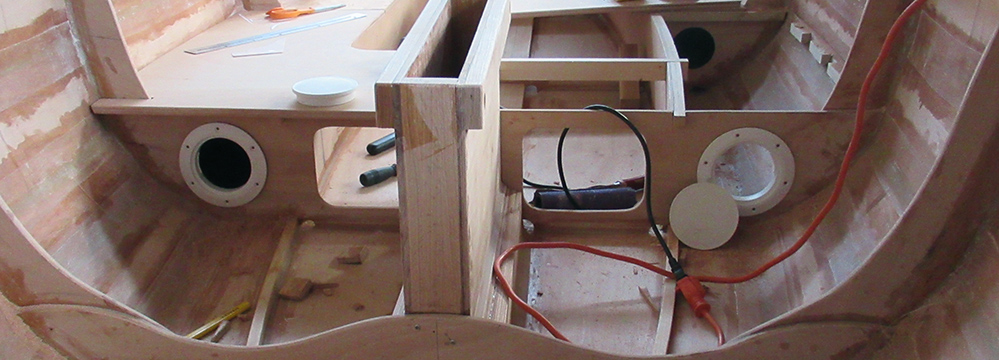

I'm also adding an inspection port to each side floatation chamber.

They're smaller 4 inch pop-out ports primarily for ventilation when needed.

An interesting upcoming project will be to design a knee to tie the inwale, transom and side wall together.

Meanwhile there is a foot of snow predicted for tonight and the temperature continues to drop.

December 8, 2019

The snow came, temperatures continue to be low, but a little work continues...

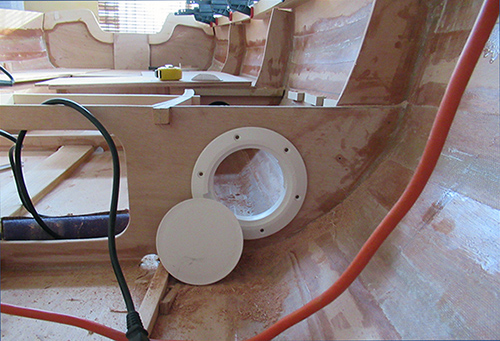

I finished up the last inspection port hole.

The port housing is temporarily in place.

Now all four floatation chambers have inspection port access.

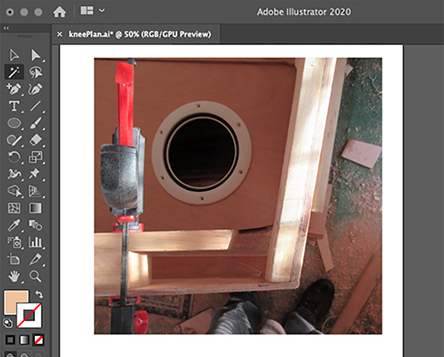

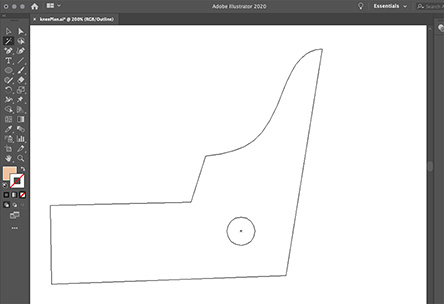

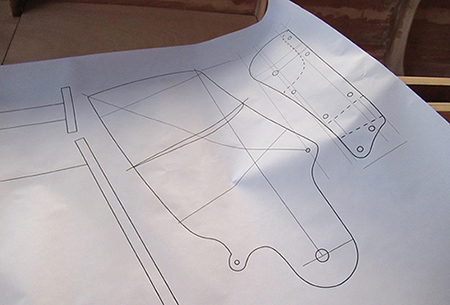

Moving on to the knee, I took a photo looking straight down on the general area and imported the image into Adobe Illustrator.

Then drew what to me looks like a nice knee shape.

By taking some measurements off the boat I was able to scale it up to actual size and print out a pattern.

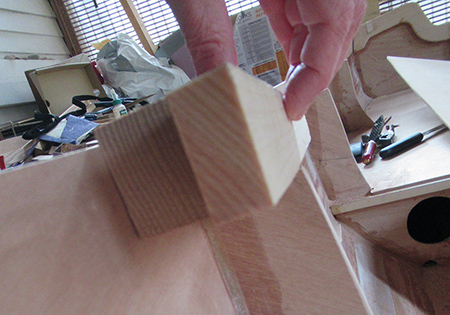

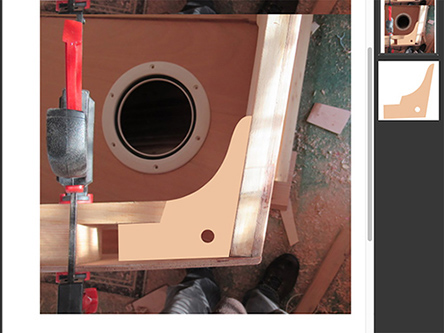

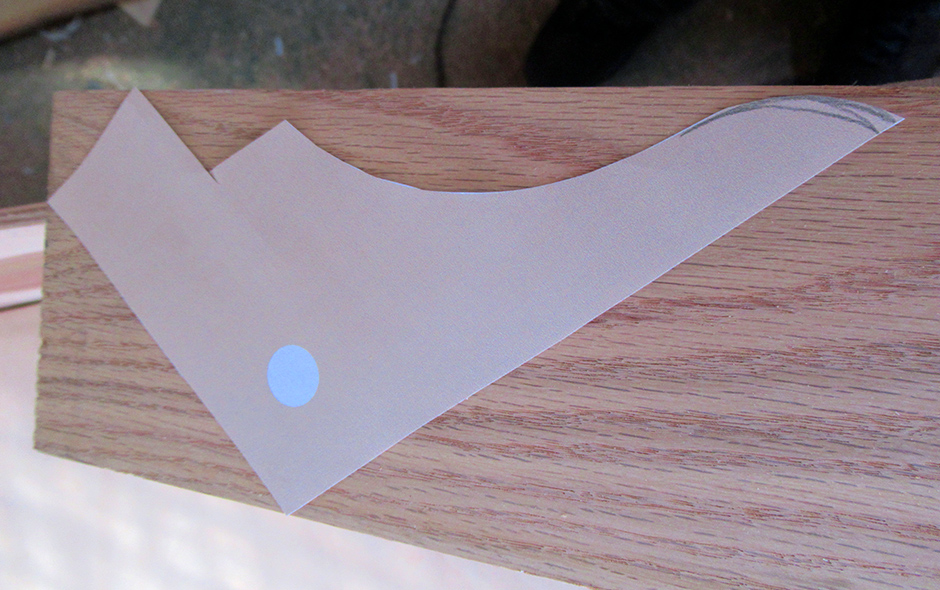

Shortening the curved end slightly got it to just fit on an oak board I happened to have around.

Here's the rough cut first attempt.

A better fit. The inwale is still under a lot of tension and I'm sure the position will change when all is glued in place, so I'm going to wait to do any more fine tuning on this fit.

The mention of tension on the inwale made me think I should get the other one in place to prevent the frame from being pulled out of alignment.

Since deciding not to run a heater overnight, it looks like the use of epoxy, glue and paint are out of the picture for a while. As a result, production will be slowing down for a few months. I will try to work on the rudder, daggerboard and tiller but I need to purchase additional wood and set up an indoors work space. I'll also continue with small projects like those from this week.

December 15, 2019

December 15, 2019

The holiday season is taking its toll on boat construction. I had just a few short time slots available this week but managed to take care of a couple things...

Based on the plans, I drew up and printed full-size line drawings for the rudder components and dagger board.

Then contrary to what I said last week, I continued to work on the quarter knees. After carefully measuring, repositioning and tightly clamping the inwales and blocks in place, I feel fairly confident I can finalize the knee shape.

There will be some additional clean up when all is glued into place.

A clamped down drill equipped with a little sanding disc helped clean up the curved edge.

And here is the starboard side – glad to have this project completed. Now I can go forward with gluing it all in place the next chance I get. [EDIT: An overly optimistic statement – see next section.]

December 22, 2019

It's looking like boat building will have to take a break for the holidays. Thank you to those who have sent email comments throughout the build. Best to all – see you in 2020!