Ribs

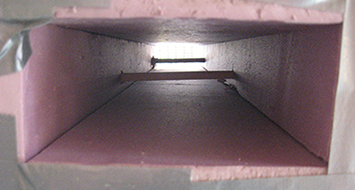

A steam box – made from styrofoam insulation and duct tape.

A couple pointed sticks pushed through the sides will elevate the ribs and allow steam to surround the wood.

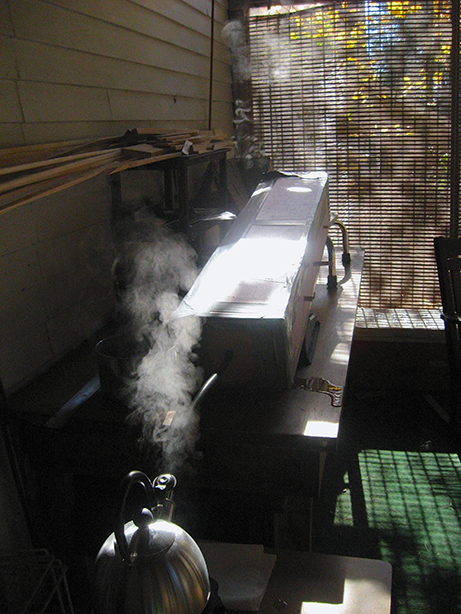

The "power plant" – a tea kettle and single-burner hot plate.

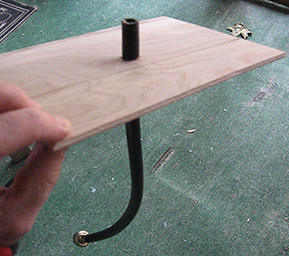

To connect the tea pot to the steam box, I clipped a washing machine hose and snuggly fit it through a hole drilled in a piece of luan plywood.

The hardware at the other end of the hose happened to fit exactly into the kettle spout.

On my last project I got lucky and located some air-dried ash to use for the ribs – no luck this time so I purchased a supply of pre-cut Northern white cedar ribs from the Berkshire Boat Building School.

Here's the steamer all fired up with a lucky rib inside.

This broom handle temporarily reinforced the keel keeping the ribs flat – a tip from Hillary Russel's book. I wedged other miscellaneous pieces of wood in at various angles to nudge the ribs into smooth, symmetrical shapes as they cooled. More details on how the ribs are bent into place can be seen in the Ribs secion of my Arrow canoe build.

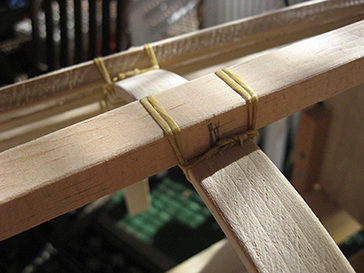

All the ribs are zip-tied in place.

Then the zip-ties were removed one at a time and replaced with lashing.

All ribs lashed into place.

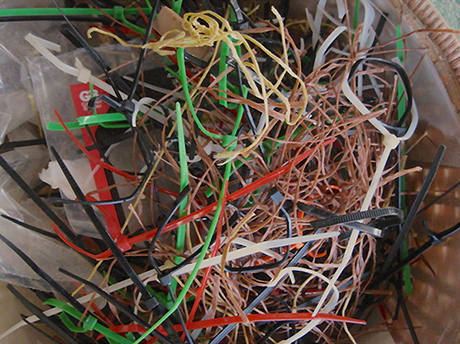

The scraps – looking like a Jackson Pollock painting!

Ribs were glued to the gunnels.

A wide view of the screened porch "workshop".