Ribs

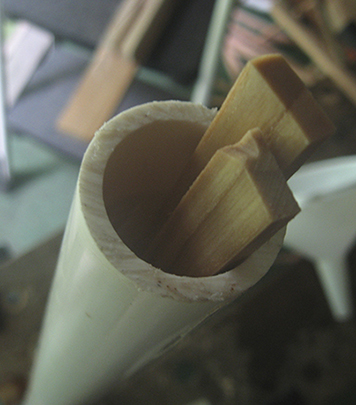

This setup worked perfectly for bending the Arrow's lightweight ribs. It's comprised of a 4-1/2 ft. piece of 1" PVC pipe, a cap pressed onto the bottom and a plastic funnel at the top.

I lifted the funnel and dropped 2 ash ribs into the pipe...

...then filled the tube with boiling water - didn't take much.

After about 7 minutes in the boiling water the ribs were flexible enough to handle the required bends. I had no breakage or misshapen ribs throughout the entire process. (All those scraps in the background are leftover stringer pieces.)

A heated rib was swiftly inserted under the stringers. Then the pre-marked center of the rib was pulled up and clamped to the keel.

The rib was then pushed up and pulled outward until it rested against the inside of each stringer.

The joints were all clamped, then I repeated the process with the second heated rib working 2 ribs at a time. While the next 2 were submerged in the boiling water, I replaced the clamps on the current 2 with zip-ties.

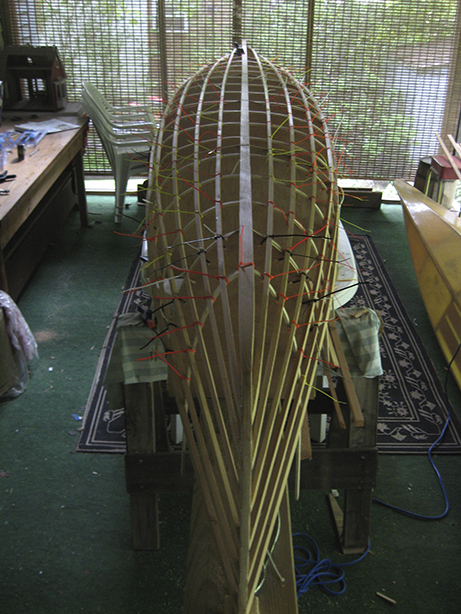

All the bent ribs are in place (the last rib at each end is made from 2 pieces to accommodate the tight radius).

This sea of zip-ties is holding the ribs in place until they dry. Once dry, they can be glued to the stringers - but I chose to lash them.

I decided early on to forego building a true "Airolite" boat as described by Platt Monfort and to incorporate ideas from other skin-on-frame building techniques.

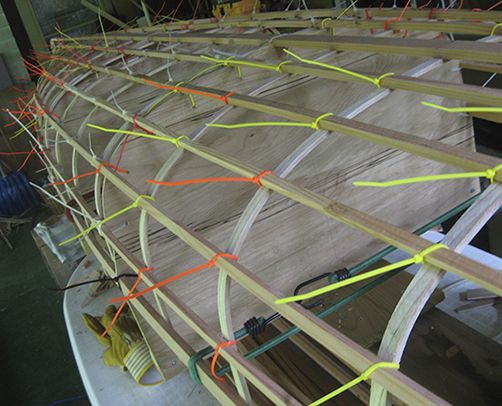

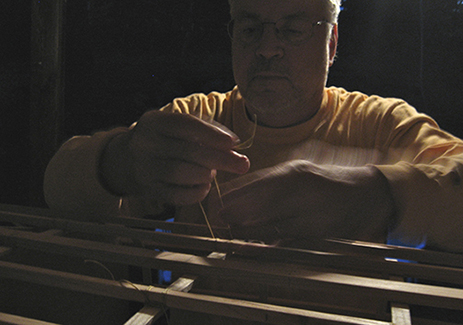

Working a few rows at a time, I removed the zip-ties and lashed the ribs to the stringers using artificial sinew.

Here's a close-up of the lashing. I used the pattern described in the book "Building Skin-on-Frame Double Paddle Canoes" by Hilary Russell of the Berkshire Boat Building School, also illustrated in his article in Wooden Boat magazine #205.

The ribs were glued (rather than lashed) to the gunwales because the inwales need to lie flush against the inside of the ribs.

Once the glue dried, the strong back and station forms were no longer necessary.