Reskinning

With no place to store the Sea Tour, it was left outside on a pair of sawhorses for about 10 years while attention was focused on the 3 newer boats.

Out in all kinds of weather, mold started to form and the coating began to peel.

Although, from what I could see, the frame still looked good. So still having need for a mid-sized touring kayak, I decided to try to reskin it.

Not knowing where to start, I turned to YouTube and found Brian Schulz, of Cape Falcon Kayaks had posted a video of the entire process.

It begins with using a razor-blade knife to cut off the old skin.

The skin was surprisingly easy to remove once the first cut breaks through the skin.

The coaming was a separate challenge since the skin is sewn onto it.

A surprising amount of surface mold had accumulated under the skin.

With some washing and light sanding it cleaned up pretty well.

The frame was in still in excellent shape except near the tips where it had also developed a little mold.

After a clean up, I reinforced it with a thickened epoxy.

I took the opportunity to reshape both ends slightly — more to my current tastes.

Two additional support strakes were added to round off the deck a bit.

Two coats of tongue oil completed the frame.

Wanting to try something different with the skin, I used 14 oz. polyester and decided to coat it with PL Primer (as promoted by Dave Gentry) and Latex paint.

I also used a welting cord sewing method (Corey Freedman), wrapping the polyester around 2 lengths of paracord before stitching together.

I started stitching with unwaxed dental floss but switched to 30 lb. braided fishing line because the floss was hard to work with and frayed if it snagged on anything.

These fairly large wrinkles emerged while sewing the coaming on.

Thankfully, the heat-shrinking capabilities of the polyester combined with some heat from a heat gun removed them entirely.

The wrikles completely disappeared.

And the skin was drum tight over the entire surface.

PL Premium adhesive was used to smooth the weave and strengthen the skin.

It was applied to the surface.

Then spread thinly and scraped to leave just a thin coating.

I gave it several coats of Rustoleum primer.

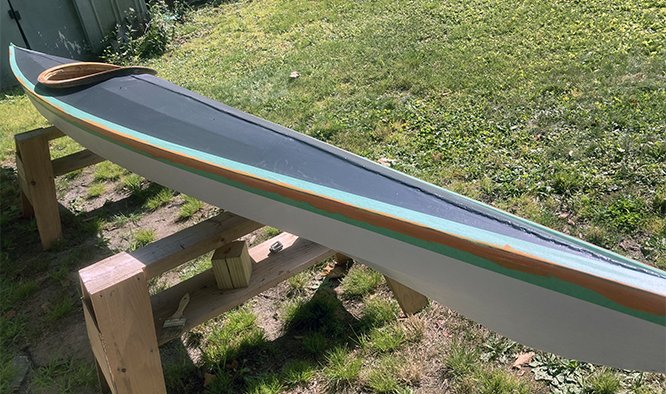

Then used more oil-based Rustoleum to paint the hull white and the deck dark gray with light sanding between coats.

Here it is taped to add an accent line along the shear.

The color choices with Rustoleum are very limited so I mixed up some yellow and red to make this orange stripe.

The final result feels like a brand new boat!

A great Autumn boat with its durable skin and enclosed deck to provide warmer and dryer paddling.