Skinning

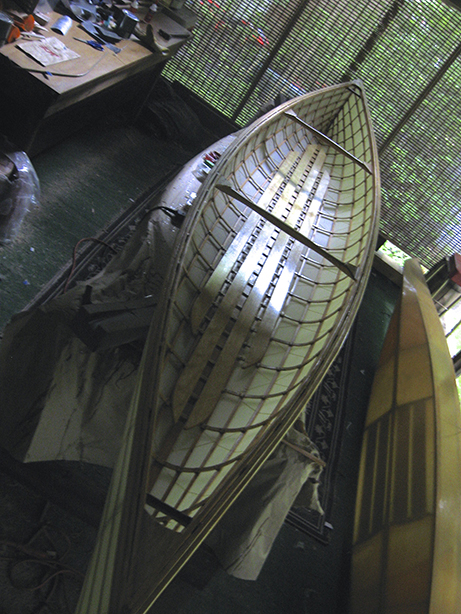

Following Platt Monfort's intructions, a strip of Heat-'n-Bond 2-sided tape is applied to the gunwales. It's used to secure Kevlar roving that's applied in a cross-hatch pattern over the frame. This step is part of the aircraft construction heritage this building technique is based on – purportedly it adds rigidity to the frame.

The Kevlar roving is secured between 2 layers of Heat-'n-Bond tape at the gunwales. The tape is heat activated with an iron and adheres as it cools. The Kevlar is comprised of thin strands that tend to bunch up and require repeated smoothing to lay flat.

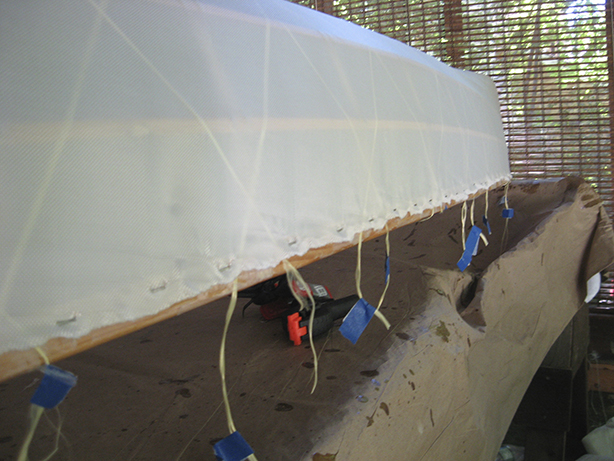

The material is 8 oz. heat-shrinkable polyester cloth purchased from George Dyson. I first spread the material completely over the frame, smoothed it out and clamped it in place to remove any major wrinkles.

Then, the skin was pulled down tightly and attached along the gunwales with stainless steel staples.

At the ends, one side was stretched across the stem piece and stapled.

Then it was trimmed off as shown and the second half stretched across the first, stapled and trimmed.

I used a soldering iron with a knife-like tip to trim the cloth. It cuts while melting the edge to prevent fraying.

The polyester shrinks when heat is applied to it, so, repeatedly running an iron slowly over the cloth pulls the skin drum-tight. When the skin shrinks, it tightens the entire frame which unfortunately loosens the Kevlar. The heat-'n-bond must be reheated to release the adhesion and allow the kevlar to be pulled tight again. Once re-tightened, the dangling ends are clipped off.

Here a shot taken before the Kevlar roving was trimmed and before the rub rails were reinstalled. The rub rails will hide the staples and the roughly trimmed edge of the cloth.

The rub rails were attached with screws. Holes were predrilled and went through the rub rail, through the gunwale, through the rib and slightly into the inwale. So they help hold the entire gunwale assembly together.

Here is the completed frame, now skinned and ready for waterproofing.

The skin was covered with 5 coats of oil-based polyurethane varnish to seal and waterproof it.

After sealing, I added a brass rub rail (attached with screws) down each stem for protection and to cover the staples and ragged trim line along the stems.